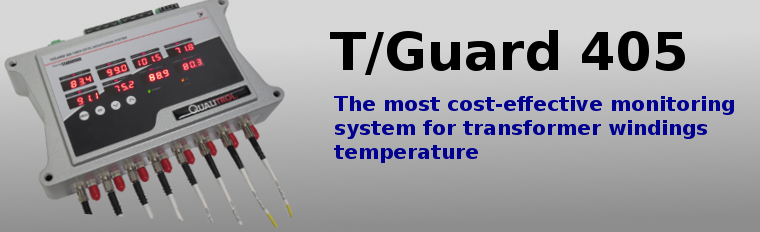

T/Guard 405 System for Transformer Hot Spot Monitoring

Description

- No calibration or maintenance ever

- Probes requires no gage factor or calibration

- 32MB datalogging memory

- RS-485 and MODBUS communication

- Voltage or current output

- Accuracy of ±1°C

- Available with 2 to 16 channels

A multichannel fiber optic system for high voltage and transformer hot spot temperature measurement

For a product brochure of the T/Guard 405 Signal Conditioner, please contact Neoptix

The Neoptix™ T/Guard™ 405 is a multi-channel fiber optic temperature monitoring system for power transformer hot spot measurements. The T/Guard 405 system has been developed with long-term performance and stability in mind. This fiber-optic temperature monitoring system for power transformers offers accuracy, toughness and long-term resistance to failure.

Coupled with the T/Guard 405 system, the Neoptix™ T2™ fiber-optic temperature probe provides accurate and direct temperature monitoring of transformer windings. This solution provides a realistic, real-time view of winding conditions that is quicker and more accurate than top oil thermocouple measurements, and greatly complements indirect measurements based on thermal models.

The Neoptix™ T/Guard 405 system gives the exact temperature of probes in 250 millisecond per channel. Peak load or emergency overloads are thus detected almost instantaneously. With Neoptix technology, you have then best tools to optimize high-voltage transformer performance and life expectancy.

The Neoptix™ T/Guard 405 system is specifically designed to meet power transformer industry requirements: extended intervals between servicing, low maintenance, rugged components and the ability to withstand the harshest conditions. All components have been specifically selected for long term performance, including the light source that has an MTBF superior to the life of the transformer. Moreover, compared to other technologies available on the market, like fluorescent decay, our sensor, based on solid state semi-conductor, do not fade or drift over time, allowing a constant and absolute temperature measurement of your transformer windings over the lifespan of the equipment.

Our fiber-optic probes are made only with dielectric materials and are designed to withstand initial manufacturing conditions, including kerosene desorption and heat runs, as well as long term oil immersion and vibration. Moreover, the Neoptix™ temperature probes are interchangeable and no calibration or inconvenient gage factors are required when changing sensors.

The system is based on the proven solid state GaAs technology. An original algorithm is used to analyze the signal and provide repeatable and reproducible measurements.

The T/Guard 405 System is available with 2 to 16 optical channels and comes standard with a large LED display. Power consumption of the system is 15 watts.

The mounting holes are integrated directly into the T/Guard 405 enclosure, which allow a clean and robust installation into your control cabinet or substation. It is optionally available mounted in a NEMA4-12 enclosure. Automatic cooling and heating could be ordered with this protective enclosure.

The T/Guard™ 405 system comes standard with a 32 Megabytes on-board datalogging memory that allows utilities and transformer operators to record temperature data points and alarm status information directly into their T/Guard 405 temperature monitoring system, without the need for permanent connection to a remote acquisition system. The T/Guard 405 option is delivered with a 32MB memory size, which is sufficient to log over 450,000 data points. This represents more than eight years of data logging for a transformer instrumented with eight temperature transducers. The T/Guard 405 system is a completely independent monitoring solution and the logged file can be retrieved by a PC using RS-485 serial communication. Data points are saved with a time stamp that comes from the internal real-time clock of the T/Guard 405 System.

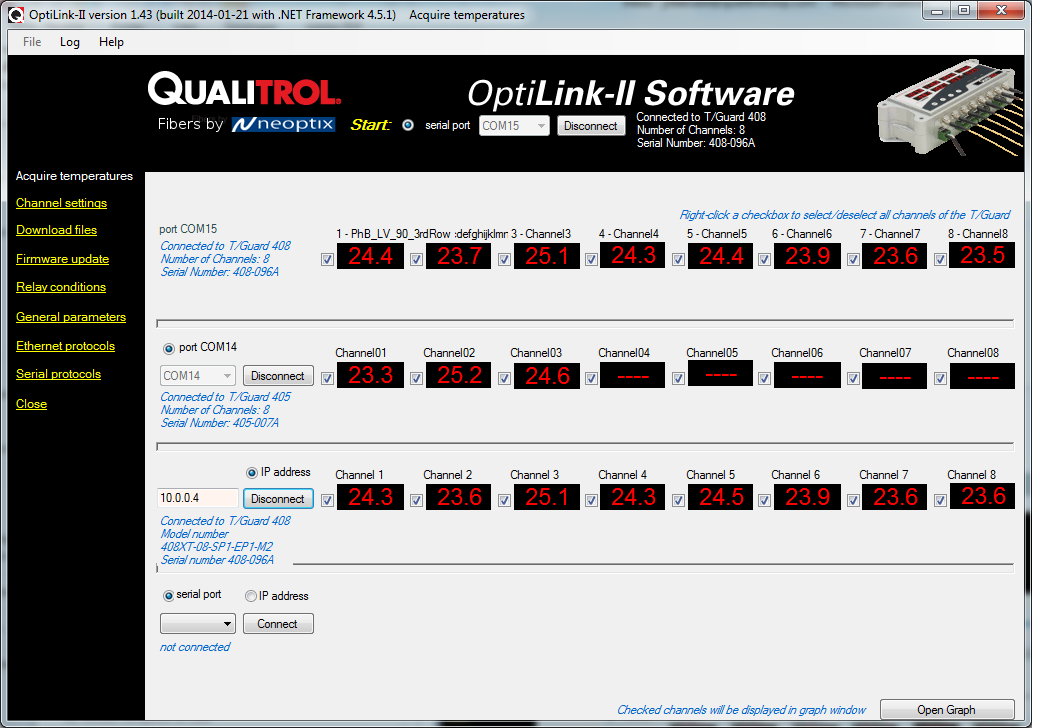

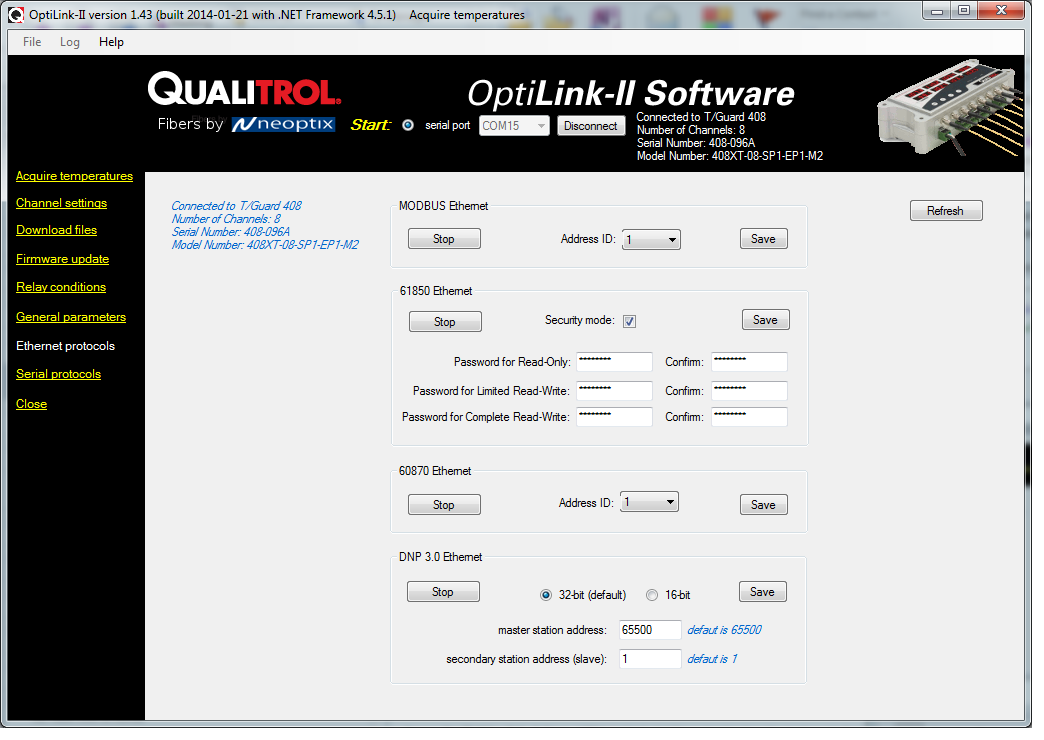

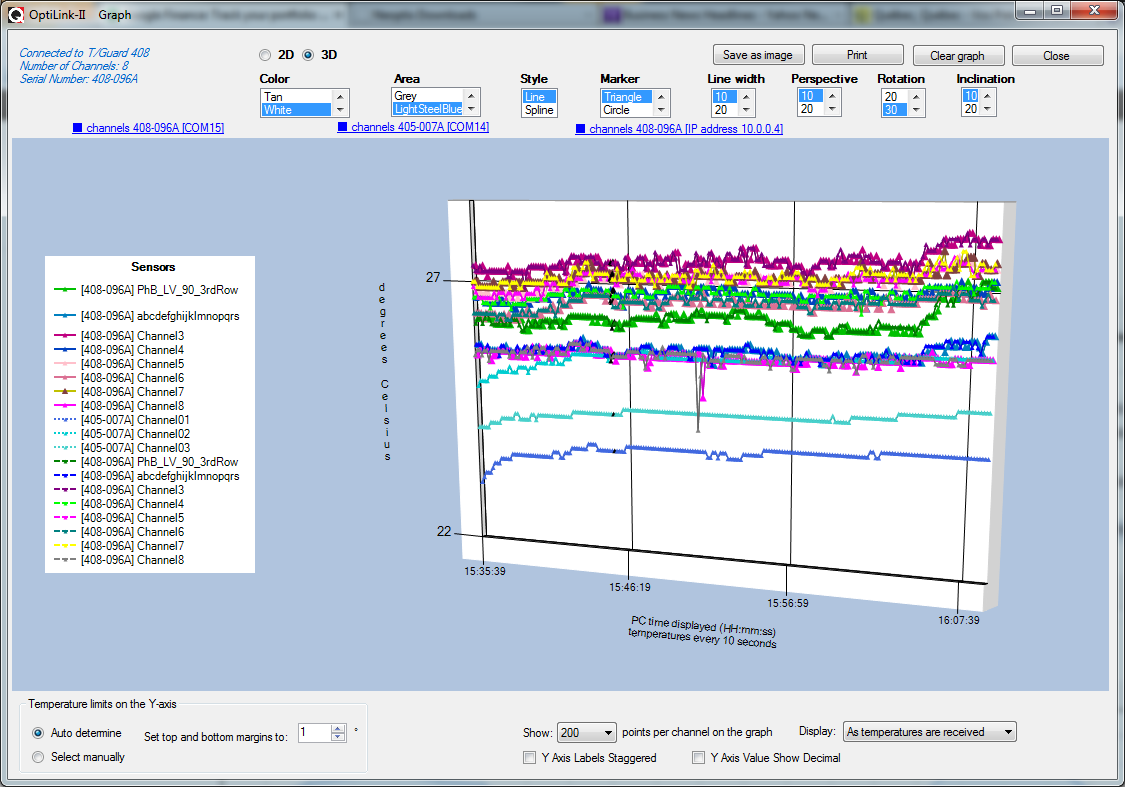

The T/Guard 405 system is easy to interface to an existing marshaling or substation system via its 4-20 mA analog outputs (0-10 Volts optional) or its MODBUS communication interface. When used with the optional Neoptix OptiLink™ software on the serial port, the T/Guard becomes an indispensable monitoring instrument.

T/Guard 405 System is covered by a complete 5-years warranty

![]()

Literature/images

LITERATURE

For a product brochure of the T/Guard 405 Signal Conditioner, please contact Neoptix

IMAGES

Accessories

Specific accessories specifically designed to complement and enhanced your T/Guard 405 System fiber optic signal conditioner:

T/Guard transport case (Part: 405-CAS)

Protective case for T/Guard signal conditioner, aluminum with foam to fit signal conditioner, sensors and accessories

RS-485 to USB adapter (Part: NXP-341)

USB to RS-485 adapter, with a 0.5m cable and a terminal block for connection to the serial port of the T/Guard-408 system. Include a 1-meter USB cable. Ground isolation of 2,000V. With software drivers for Windows.

NEMA Enclosure for T/Guard System (Part: NXP-300)

NEMA-4 water, oil and dust tight protective enclosure for T/Guard 405 System signal conditioner. Made with 14GA steel, finished with heat fused polyester powder, electrostatically applied on a phosphatized base. AINSI/ASA 61 grey. NEMA-4-12/IP66.

Heating for NEMA enclosure for T/Guard 405 System (Part: NXP-310)

Heating option for NEMA-4 enclosure for "T/Guard" 405 signal conditioner, controlled with automatic thermostat, 550 Watts heater, specify 120V or 220VAC.

DIN rail power supply for T/Guard System (Part: TGD-DPS)

DIN rail mountable 24 VDC universal (100-240VAC @ 47-63 Hz), 0.6A, power supply for your T/Guard Signal Conditioner.

OptiLink-II Software control and datalogging software